Customised Fabricated Solutions

With over 30 years manufacturing expertise in the rotational moulding sector the company also applies its plastic design and manufacturing expertise to offer customised plastic fabrication solutions.

Custom Plastic Fabrications

We design, develop and manufacture bespoke products tailored to customer specific requirements. Our blend of market knowledge and technical expertise allows us to deliver distinctive customer service from initial project specification through to project completion. We endeavour to respond quickly to changing customer needs and market developments.

Additional Information

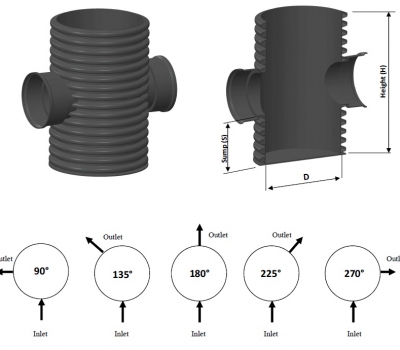

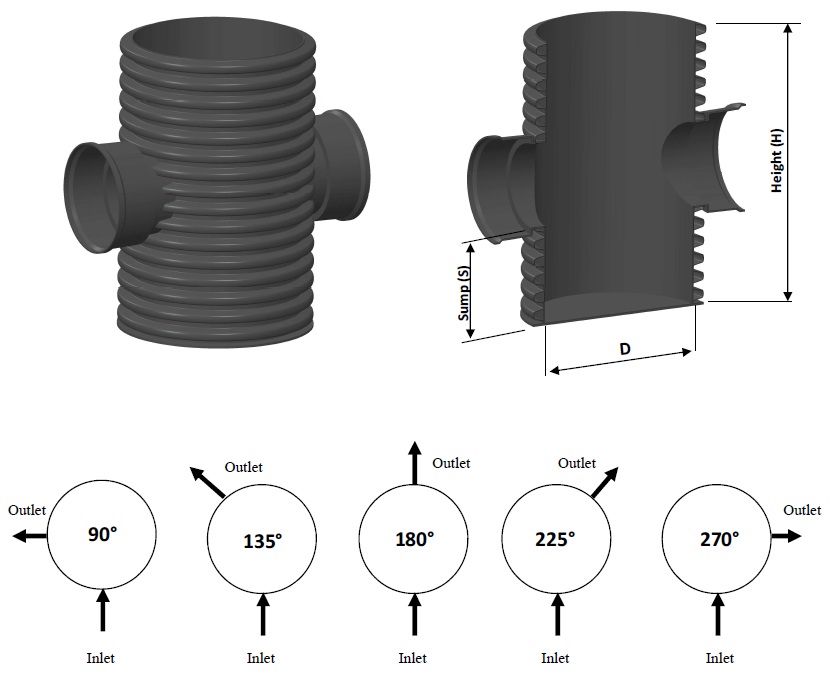

We have a range of Catchpits/ Silt traps to separate silt and other particles. This improves the quality of water before it is reintroduced back into the drainage system.

As each individual SuDS system is different, they are individually fabricated to take into account water flow rates and ground conditions that differ from site to site. JFC catchpits have been widely and successfully used for applications including railway and highway drainage systems. Bespoke fabrications are made to order as per customer project requirements. They can be installed in depths up to 6 meters and with any number of inlet and outlet quantities, sizes or configurations. Contact JFC today to discuss your project further.

Specification:

| Material | High Density Polyethylene |

|---|---|

| Application | Surface & Stormwater Drainage |

| Base Plate | Fully Welded |

| Connections | Spigot as standard

(Couplers on request) |

| Catchpit Diameters (Ø) | As per table below |

| Inlet & Outlet Sizes | As per table below |

| Sump Depths (s) | 300mm standard* |

| Height (H) | As requested* |

Sizes:

| Catchpit Diameter (mm) | Inlet & Outlet Sizes(mm) | Standard Sump (mm) | Max Depth. Available (mm) |

|---|---|---|---|

| Ø450 | 150 & 225 | 300 | 2000 |

| Ø600 | 150, 225 & 300 | 300 | 2000 |

| Ø750 | 150, 225, 300, 375, & 450 | 300 | 2000 |

| Ø900 | 150, 225, 300, 375, 450, & 600 | 300 | 4000 |

| Ø1200 | 150, 225, 300, 375, 450, & 600 | 300 | 4000 |

| Ø1500 | 150, 225, 300, 375, 450, & 600 | 300 | 4000 |

| Ø1800 | 150, 225, 300, 375, 450, & 600 | 300 | 4000 |

| Ø2100 | 150, 225, 300, 375, 450, & 600 | 300 | 4000 |

Features & Benefits:

- Fast Installation

- Pre-Fabricated

- Bespoke as per customer specifications

- Designed to fit JFC CorriPipe™

- Catchpit covers available on request

Quality Assurance:

JFC Catchpits – Network Rail Certificate of Acceptance PA05 / 05929

Product Gallery

Surface water drains normally discharge to a watercourse or indirectly into underground waters via a soak away. Contamination of surface water by oil, chemicals or suspended solids can cause these discharges to have a serious impact on the receiving water. Interceptors protect receiving waters from such pollutants.

Operation:

Interceptors remove pollutants from effluent and allow cleaner water to pass into a surface water drainage system. Pollutants are retained for removal and disposal. Interceptors work by allowing the pollutants and water to naturally separate. Pollutants float to the surface of the water for easy removal. Silt settles within the unit and can be easily removed. All JFC Inceptors are manufactured to IS EN ISO; 9001:2000 and conform to European Standard PR EN 858 – 1 & 2.

ByPass Interceptor

- Used on low risk sites (Car Parks)

- Sized in litres per second flow

- Available in Class 1 format

Sizes:

| Product Code | Drainage Area (m²) | Nominal Flow (L/s) | Peak Flow (L/s) | Oil Storage (L) | NSB Ref |

|---|---|---|---|---|---|

| BPDA1950 | 1,950 | 3.5 | 35 l | 52.5 | 3.5 |

| BPDA2500 | 2,500 | 4.5 | 45 | 67.5 | 4.5 |

| BPDA3300 | 3,300 | 6.0 | 60 | 90 | 6 |

| BPDA4400 | 4,400 | 8.0 | 80 | 120 | 8 |

| BPDA5555 | 5,555 | 10.0 | 100 | 150 | 10 |

| BPDA6900 | 6,900 | 12.5 | 125 | 187.5 | 12.5 |

| BPDA8300 | 8,300 | 12.5 | 125 | 187.5 | 12.5 |

| BPDA10000 | 10,000 | 18 | 180 | 270 | 18 |

| BPDA13333 | 13,333 | 24 | 240 | 360 | 24 |

Best Management Practice:

Best management practices should be maintained to ensure a clean network at all times. Sinkable solids and floatable contaminants should be prevented where possible from entering the unit by means of a dedicated silt traps and/or sumped catchpit manhole (s) upstream thus preventing potential problems.

It is important to note that a large amount of the settable solids are present in the network during construction and this is mainly due to the silt/grit present in construction runoff. To account for this, the following inspection and maintenance guidelines are recommended as best management practice:

- Initially inspect the catchpit manholes on a monthly basis (periodically thereafter)

- If cathchpit is 30% full, de-sludge the catchpit (s) with a standard vacuum tanker

- If large amounts of silt present, additional catchpit manholes with 90 degree bends may be required

- When construction is finished a full camera inspection is recommended on the network

- Any contaminants found in the line should be flushed/jetted and the catchpits de-sludged

Product Gallery

CONTACT A MEMBER OF OUR SALES TEAM TODAY

Click here ask us a question, or request a call back to discuss your requirements today!